The effect of perception on safety and ergonomics

I’m going to continue my blog series about why employees who’ve received safety and/or ergonomics training still don’t do the things they were trained to do. It’s been my experience that there are at least four main reasons for people not to follow through on what they’ve been taught. In my last blog I talked about habits. Today, I’m going to cover the second common reason: perceptions. Perception means the act or faculty of apprehending by means of the senses or of the mind; cognition; understanding.

Perception is very interesting. Our perception, or our ‘reality’, is based upon our experiences. Our senses, our eyes and ears and to a lesser extent our nose, skin, and tongue, feed us signals. We attempt to make ‘sense’ out of it all by making mental models of what we think those signals actually mean. Our ‘reality’ is shaped when we are successful in putting together a mental model that is consistent. We then judge other signals or behaviors based upon our model.

If something fits our past experience, then it confirms our model, and we say that it ‘makes sense.’ On the other hand, if something doesn’t fit our mental model, then more often than not we are likely to reject it. We tend to think and say that it ‘doesn’t make sense’ or that the other person doesn’t have ‘common sense’ or that suggestion/recommendation will never work for us.

So does a person’s perception affect how they perform their job? Absolutely. Does it affect how they follow safety and ergonomic policies and procedures? Again, absolutely. Let’s take a recent experience of mine as an example. I was recently in a foundry to do an ergonomic analysis. I was observing the knock-off area in where the parts are separated from the gate. Two employees were positioned on either side of the moving, vibrating conveyor. They were to switch sides every hour. The ‘safe’ way to switch sides is to walk down a flight of stairs, walk around some other machines and then back up another flight of stairs. During my observations of the three different shifts none of the employees did it that way. Instead they switched sides by stepping on and walking across the conveyor to the other side. The risk of getting seriously hurt by making a wrong step on a moving conveyor with hot iron parts is quite high, however, none of them thought what they were doing posed a safety risk. Had the employees been trained to avoid walking on the conveyor because of the hazard? Yes. Did they believe it? No. Why? They and their co-workers have done it that way for a long time and no one had gotten hurt. They perceived no threat.

The second perception they had was that walking around would take too much time and they would fall behind. In reality, the rate at which the parts were coming down the conveyor allowed adequate time for them to make switch doing it the safe way without falling behind. However, their perception, their ‘reality’, caused them to repeatedl

y perform an unsafe act which then becomes a habit (see last week’s blog

Our perceptions affect us at home, work and play. In order to attempt to determine the affect our perceptions have on us, our business and our work we need to ask ourselves the following questions: How often do our perceptions

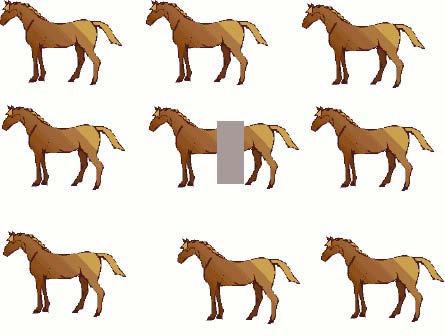

The horse in the middle looks longer even when surrounded by normal horses. Adapted from I. Rock (2001)

mismatch with reality? What do we ignore when we mismatch? What hazards and opportunities do we fail to recognize because we match too quickly and easily? On the opposite side, what hazards and opportunities do we let pass by unaddressed because we couldn’t ‘see’ them?

Ergonomics and human factors have to be utilized to counteract perceptions in order to avoid costly errors (human health and financial loss). What common perceptions have you seen that are different from reality?

I’ve covered two out of the four main reasons for why people don’t do what they’ve been trained to do. In my next two blogs I’ll cover the last two reasons. Then in the following blogs I’ll address how to approach these common reasons using ergonomics and human factors.